[SUNLU FilaDryer E2] The newest pop-up in 2025, made for engineered materials, helps infinite creation, drying and annealing in one.

[Superior and Efficient Annealing] Up to 110°C, it can anneal 99.99% of engineering materials on the market, allowing the materials to fulfill their potential and giving your model excellent properties such as extraordinary impact resistance and toughness. Suitable for such as ABS, ABS-CF, ASA, PC, flame retardant PC, PC-ABS, PC-PBT, CoPA, PA6-GF, PA6-CF, PA12-CF, PA612-CF, PA12 etc...

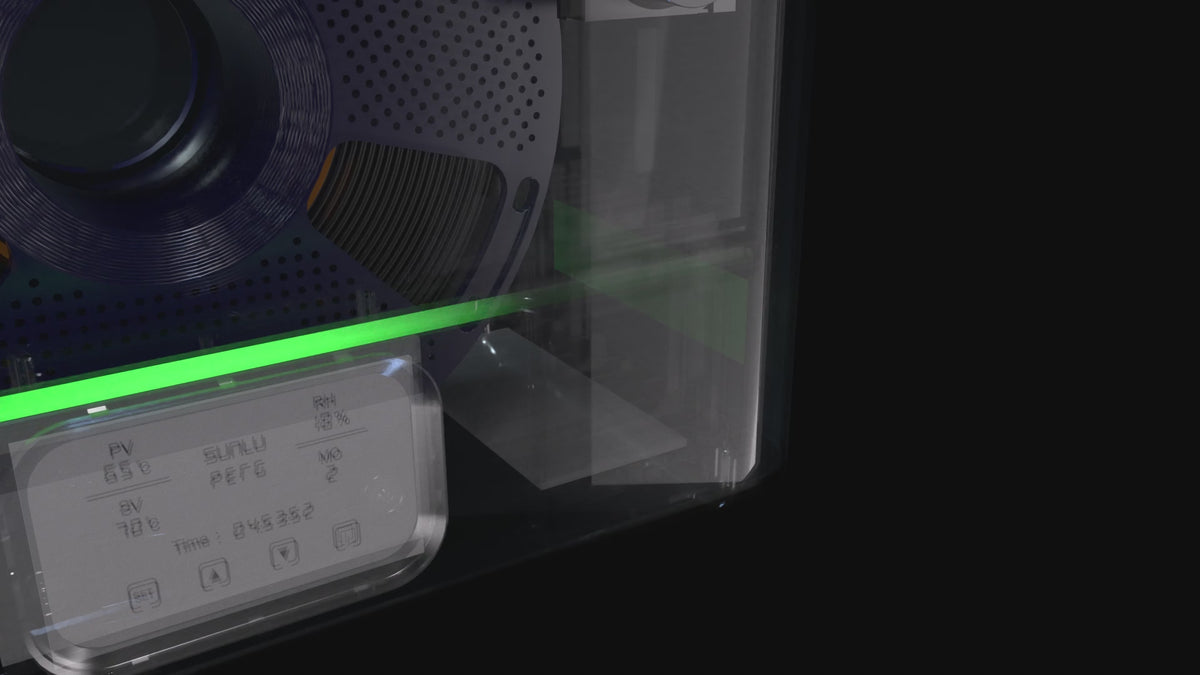

[Fast and Efficient Drying] 500W PTC ultra-high heating power makes your creation a step faster. It takes only 20 minutes to heat up to 50℃ at room temperature and 30 minutes to heat up to 70℃! Temperature can reach up to 110℃ (high temperature drying needs to take into account the temperature resistance of the filament spool)

[Excellent Airtightness, Super Insulation Effect] One-piece silicone plug over the line hole, the cover plate is equipped with sealing silicone strips and magnetic suction block, to isolate the outside water vapor into the chamber. The all-round dual-chamber design at the top, middle and bottom realizes the heating temperature exceeding 100°C. Combined with the innovative closure system, the annealing process is more perfect, solving the two needs of annealing and drying in one machine.

[Extra Large Interior Space, Super Adaptability] The maximum compatible spool size is Φ250mm*153mm, which is suitable for most of the regular spools on the market. Tested, it can hold 2 reels of regular 1KG spools, 1 reel of regular 2KG spools or 2 reels of regular 3KG spools. (Note that the test spools are SUNLU spools, other brands of spools will have slight differences, but basically compatible, when using the need to pay attention to the size of the spool.)

[Strong Compatibility, Adapts to 99% of the use scenarios] Can be applied to both engineering materials and conventional materials. Built-in preset filament settings, one click to apply the preset. The wire diameter is compatible with most of the materials on the market (Φ1.75mm, Φ2.85mm), and the Teflon tubing included with the product is Φ4*Φ3mm in size and 8cm*2 and 1m*2 in length.

[Strong Safety, No More Worries] Intelligent protection system, two-level temperature control switch, over-temperature will be disconnected, cooling will be restored. Double-layer heat insulation, when the internal temperature is >100℃, the external touch temperature is only <60℃. Fireproof material grade

[Inspire Engineering Material Potential] Annealing significantly enhances the impact resistance and durability of engineering materials, allowing you to unlock engineering-grade performance in every creation, which can be applied to: drone accessories, helmets, screws and nuts, blower pipes, etc. Models that need to withstand high-intensity impact and durability.

Technical Specifications

| Product Name / Model |

Filament Dryer E2 |

| Package Dimensions |

454mm×276mm×362mm(LWH) |

| Product Dimensions |

400mm×220mm×307mm(LWH) |

| Internal Dimensions |

372mm×192mm×255mm(LWH) |

The maximum size of the wire spool that can be accommodated

(take SUNLU's spools for example)

|

Φ250mm*153mm

(1KG×2 or 2KG×2 or 3KG×1) |

| Net Weight / Gross Weight |

6.1KG / 7KG |

| Operating Environment |

Temperature: 10℃-35℃

RelativeHumidity: ≤95% |

| Working Temperature Range |

35℃-110℃ |

| Humidity Display Range |

10%-90% (Accuracy±10%)

Note 1: When working temperature≥80℃, humidity sensor will start protection mode (displays<10%humidity)

Note 2: After temperature drops to 70℃, humiditysensor recovers original accuracy after about 20 hours.

|

| Timer Range |

0-99 Hour |

| Power Input (Pleaseverify local voltage compatibility) |

Please select the voltage basedon the silk-screen marking

on the sideof the product |

| Maximum Operating Current |

2.2A @230V 4.2A@120V |

| Standby Power |

≤1W |

| Compatible Filament Diameters |

Φ1.75mm/Φ2.85mm/Φ3.0mm |